Scientists from the Analytical Chemistry Division and the U.S. Food and Drug Administration have maintained a thermal neutron prompt gamma-ray activation analysis (P G A A) facility at the N C N R for the past 25 years. The facility is used routinely for analysis of major and minor element compositions of a variety of biological, environmental and industrial materials. Recent applications include determination of: several elements in Standard Reference Material (S R M) 1575 A, Pine Needles; cadmium in S R M 2702 Inorganic Sediment; nitrogen and phosphorus in cattail samples in collaboration with Florida A & M University; boron in sapphire in collaboration with Southern University; and nitrogen, sodium, phosphorus, sulfur, chlorine, potassium, calcium, and cadmium in food, dietary supplements, and other food-related matrices.

A new thermal neutron P G A A instrument became operational in 2001, replacing the original thermal neutron P G A A instrument that was built in the late 1970's. The new instrument was designed and built to improve analytical sensitivities and limits of detection, and decrease the levels of radiation associated with use of the instrument. This was achieved by filtering the neutron beam to decrease the fast neutron and low energy gamma-ray components of the beam, designing the new facility components and support structure to minimize neutron capture gamma-rays, and installing an improved detection system. The new thermal neutron P G A A facility is shown in figure 1.

|

Figure 1. New thermal neutron P G A A facility at V T 5 |

A cylindrical sapphire beam filter 5.3 centimeters long and 4.3 centimeters in diameter was incorporated into the shutter assembly. This modification reduced the number of fast neutrons by a factor of 5, decreased the thermal neutron flux by approximately 12 %, and greatly reduced low-energy gamma-ray background. With the reduction in fast neutrons, the amount of hydrogenous shielding required to slow and capture the fast neutrons was reduced as compared with that needed in the old facility. As a result, the background count-rate for the 2223.3 kilo electron volts capture gamma-ray of hydrogen has been reduced from about 1 count per second (cps) or the equivalent of about 0.5 miligrams, of hydrogen, to 0.05 cps or the equivalent of 25 micrograms of hydrogen.

A summary of the design changes for each component of the facility and their effects is shown in Table 1. The original beam tube and sample chamber were fabricated from concentric Plexiglas tubes, filled with a mixture of paraffin and boron carbide. The new sample chamber and beam tube were fabricated from aluminum and lined with a 2 millimeter thick flexible lithiated polymer (lithoflex). The beam tube is kept under vacuum to reduce background gamma-rays arising from neutrons scattered by air and captured in the surrounding materials. The new sample chamber can be evacuated to further reduce background associated with neutron scatter and capture in air. As a result of these design changes, the background count-rates from hydrogen, nitrogen, and boron have been reduced by a factor of 10 or more and carbon has been eliminated from the background. The count rate for aluminum is about the same in the new system, despite the large amounts of aluminum in the beam tube, beam stop, sample chamber and support structure.

The beam stop of the old facility was a separate unit. It consisted of a steel box containing a lithiated polycarbonate cube (30 centimeters on a side) surrounded by lead bricks. This unit was lifted into place on top of the beam tube each time the system was assembled. The new beam stop consists of an aluminum box welded onto the aluminum support structure, and is filled with a cube of borated polyethylene (20 centimeters on a side) surrounded by lead. The elimination of steel from the beam stop has greatly reduced the background count-rate from iron.

A new germanium detector with improved resolution and peak-to-Compton ratio was installed. This detector has a relative efficiency of 40 % (relative to a 7.6 centimeter cube of sodium iodide) and 2.0 kilo electron volt (peak full-width-half-maximum) resolution for the 1332.5 kilo electron volt gamma-ray line from cobalt 60. The original sodium iodide Compton suppression system was replaced with a bismuth germanate suppressor. This modification eliminated sodium gamma-ray background.

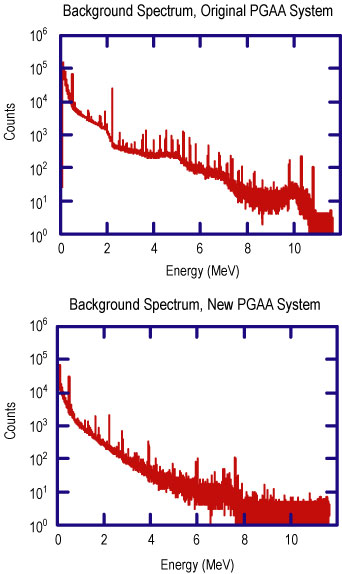

The goal of reducing background radiation and improving analytical sensitivity and detection limits has been achieved. A comparison of spectra from background counts from the old and the new P G A A systems is shown in Figure 2. The reduction in the background count-rates in the low energy region is evident. This reduction will greatly improve the detection limits for elements with neutron capture gamma-rays in the low energy region. With the sample chamber evacuated, nitrogen capture gamma-rays have been eliminated from the background. Elimination of the sodium background has improved the detection limit for this element. Improvements in shielding have resulted in a decrease in the background count-rates of hydrogen, boron, carbon, iron, and germanium, improving detection limits for those elements as well.

| Facility Component | Old P G A A System | New System | Effect |

| Beam Stop | Steel cube (61 centimeters on a side) lithium carbonate plug, cube of lithium carbonate in resin surrounded by lead bricks | Aluminum cube (43 centimeters on a side) lithium 6 fluoride polymer plug, borated polyethylene surrounded by lead bricks | Eliminate iron background gamma-rays from beam stop |

| Beam tube | Plexiglas concentric tubes with a mixture of boron carbide in paraffin, and lithium carbonate in paraffin between them; Teflon film end windows; air filled beam tube | Aluminum tubing lined with lithium 6 fluoride polymer capped at each end with Aluminum and center windows of a Magnesium alloy. Upper and lower sections evacuated, lithiated polyethylene shielding on outer two sides | Reduce hydrogen and eliminate nitrogen background gamma rays |

| Sample Chamber | Walls fabricated from tetra boron carbide in resin with Teflon windows covered with fused enriched lithium carbonate plugs in front of and across from the detector window | Welded Aluminum plate covered with lithium 6 fluoride polymer shielding; Magnesium alloy thin windows in front of and across from the detector covered with the same lithium carbonate plugs; chamber may be evacuated | Reduce boron and eliminate nitrogen background gamma rays |

| Detection Chamber | Germanium detector (27% relative efficiency) in a sodium iodide Compton suppressor | Germanium detector (40% relative efficiency) in a bismuth germanate Compton suppressor | Eliminate sodium background gamma rays |

| Support Structure | Aluminum tripod frame with a cage to hold the beam stop | Aluminum tripod frame. The beam tube and beam stop are attached to the frame and the detection system placed on rails | Improve structure stability |

| Component Set-up | Four separate pieces (beam tube, Aluminum tripod, beamstop, detection system) that are assembled individually | Assembled as one unit with a removable Germanium detector | Improve safety and ease of system set-up |

| Figure 2. Comparison of the background spectra collected with the old P G A A system (top) and the new system (bottom) |

Authors

E. A. Mackey and R. M. Lindstrom

Analytical Chemistry Division

National Institute of Standards and Technology

Gaithersburg MD, 20899-8395

D. L. Anderson

Elemental Research Branch

Food and Drug Administration

College Park, MD 20740-3835

P. J. Liposky

NIST Center for Neutron Research

National Institute of Standards and Technology

Gaithersburg MD, 20899-8561

Back to FY2002 HTML main page

Go to next article

To view all symbols correctly, please download Internet Explorer 6 or Netscape 7.1