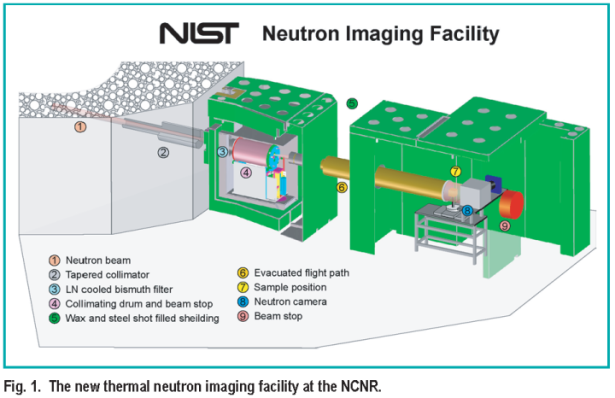

A dramatic step toward analyzing the performance and the operational characteristics of a working fuel cell has taken place at the NCNR. A new Neutron Imaging Facility ( N I F ) shown in Figure 1 has been constructed in a cooperative effort between the Department of Commerce and the Department of Energy. This facility uses neutrons to peer inside the fuel cell to view water forming and moving throughout the cell. In a fuel cell, water is formed as a by-product of the reaction between hydrogen and oxygen. If the water does not drain quickly and efficiently, then fuel cells will not work properly. Water formation is also a signature of activity in a fuel cell, so the lack of water formation demonstrates a defective area of the fuel cell.

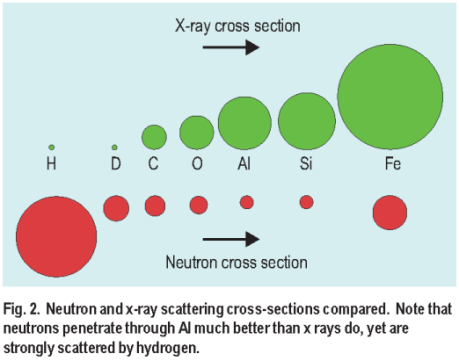

Since fuel cells are not transparent to visible light, other forms of penetrating radiation ( example: x-rays, neutrons ) must be used to analyze their operation. X-ray imaging is not suitable because hydrogen is nearly invisible to the high energy x-rays required to penetrate the metallic encasement of the fuel cell. Neutrons, which are neutral particles, can easily penetrate metals and still be extremely sensitive to water in quantities less than a microgram. The reason for this is best illustrated by a comparison of the relative scattering cross-sections shown in Figure 2.

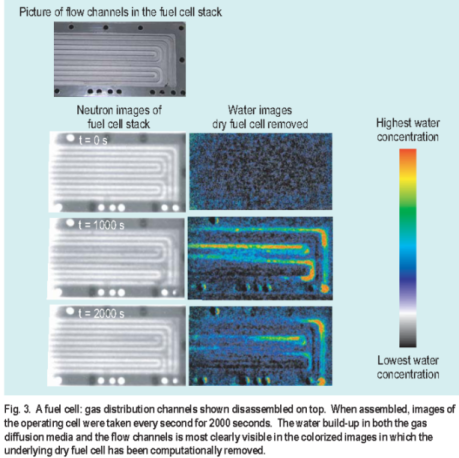

The large x-ray cross-section of Al compares to a small neutron cross-section. Conversely the x-ray cross-section for hydrogen is small compared to the neutron cross-section. This makes neutrons ideal for sensing microgram quantities of water. An example of neutron imaging fuel cells is shown in Figure 3. In the image the gas distribution system of a fuel cell shows up as the serpentine tracks. The purpose of these channels is to distribute gas evenly to the membrane and to act as a drain for water coming out. In these images the neutrons easily penetrate the fuel cell when dry. As the fuel cell runs, water builds up and appears as a darker shadow region of the images on the left. Computer analysis allows the scattering from the dry cell to be removed, revealing only the water formation in both the flow channels and the gas diffusion media, as shown in the colorized images on the right. Large amounts of water appear as red and dry regions appear as black.

Although this new facility has been constructed for the specific purpose of imaging fuel cells, it has potentially many other applications in industrial and applied research. Among these are imaging of automotive parts to study metalcasting techniques, oil lubrication in an automotive engine, and non-destructive analysis of archeological artifacts.

The very different sensitivities to various elements of x-ray and

neutron scattering illustrated in Figure 2 means that the two

techniques could be considered complimentary methods of nondestructive

analysis. Because of this broad range of applications,

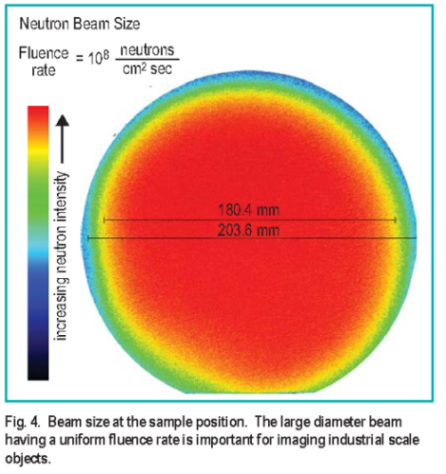

this facility was optimized for beam size, spatial resolution and

neutron flux. Currently the beam exiting the collimator traverses

4 m and bathes the sample over an 18 cm diameter circle with a

uniform neutron fluence rate of 108 cm-2 sec-1, making it possible

to image large objects ( see Figure 4. )

4 m and bathes the sample over an 18 cm diameter circle with a

uniform neutron fluence rate of 108 cm-2 sec-1, making it possible

to image large objects ( see Figure 4. )

Future detector development of this method should be able to extend time resolution to the 30 ms level and spatial resolution to the 10 μ m level. In addition, the methods of codedsource imaging could allow 3-dimensional imaging of the membrane and gas diffusion media. These developments would be able to provide a critical tool for fuel cell developers to analyze how small design changes affect a real fuel cell.

D. Jacobson, M. Arif, and P. Huffman

Physics Laboratory Ionizing Radiation Division

National Institute of Standards and Technology

Gaithersburg, MD 20899

R. Satija

Duke University Durham, NC 27708